Micro-manufacturing: Revolutionizing Production Paradigms

The concept of micro-manufacturing is taking the industrial world by storm, offering a radical departure from traditional mass production models. This innovative approach to manufacturing is redefining how businesses create products, manage resources, and respond to market demands. By leveraging cutting-edge technologies and nimble production methods, micro-manufacturing is poised to reshape the landscape of industrial operations across various sectors.

The Genesis of Micro-manufacturing

The roots of micro-manufacturing can be traced back to the early 2000s when advancements in digital fabrication technologies began to democratize production capabilities. The convergence of 3D printing, CNC machining, and other computer-aided manufacturing techniques laid the groundwork for a new era of decentralized production. As these technologies became more accessible and affordable, entrepreneurs and small businesses found themselves empowered to create products that were once the exclusive domain of large-scale manufacturers.

The financial crisis of 2008 further accelerated the adoption of micro-manufacturing practices. As large corporations downsized and outsourced production, a new generation of makers and small-scale producers emerged, leveraging digital tools and platforms to create and market their products. This shift towards smaller, more agile production units marked the beginning of a fundamental change in the manufacturing landscape.

Key Principles of Micro-manufacturing

At its core, micro-manufacturing is built on several key principles that set it apart from traditional manufacturing approaches:

-

Flexibility and Adaptability: Micro-manufacturing facilities are designed to quickly pivot production lines to meet changing market demands or accommodate new product designs.

-

Localized Production: By situating production closer to end consumers, micro-manufacturing reduces transportation costs and enables faster time-to-market for products.

-

Customization at Scale: Advanced digital fabrication technologies allow for cost-effective customization of products, even in small batch sizes.

-

Resource Efficiency: Smaller production runs and on-demand manufacturing minimize waste and reduce the need for large inventory storage.

-

Distributed Networks: Micro-manufacturers often operate within collaborative networks, sharing resources, knowledge, and capabilities to enhance overall productivity.

Technological Enablers of Micro-manufacturing

The rise of micro-manufacturing has been fueled by significant technological advancements that have made small-scale production more viable and efficient:

-

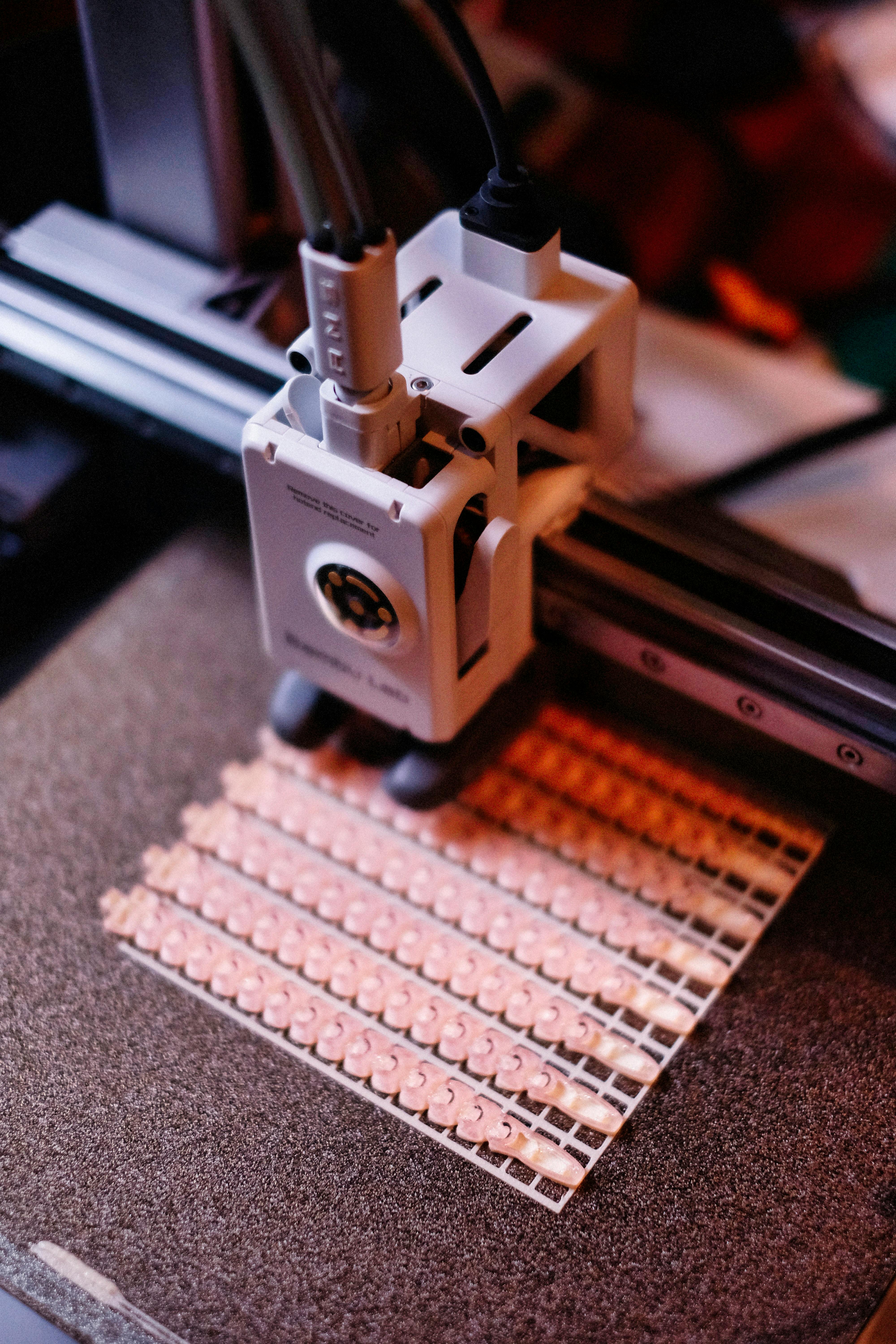

Additive Manufacturing: 3D printing technologies have revolutionized prototyping and small-batch production, allowing for complex geometries and customized designs.

-

Advanced CNC Machines: Computer Numerical Control (CNC) machines have become more compact, affordable, and user-friendly, enabling precise manufacturing at smaller scales.

-

Cloud-based Design and Collaboration Tools: These platforms facilitate seamless collaboration between designers, engineers, and producers, streamlining the product development process.

-

Internet of Things (IoT) and Data Analytics: Smart sensors and data analysis tools enable micro-manufacturers to optimize production processes and predict maintenance needs.

-

Robotics and Automation: Collaborative robots and automated systems are becoming more accessible to small-scale producers, enhancing productivity and precision.

Impact on Business Models and Supply Chains

The adoption of micro-manufacturing practices is having a profound impact on traditional business models and supply chain structures:

-

Disruption of Mass Production: Large-scale manufacturers are being challenged to adapt to more flexible and responsive production methods.

-

Democratization of Production: Barriers to entry in manufacturing are lowering, allowing startups and small businesses to compete with established players.

-

Reshoring and Localization: Micro-manufacturing is facilitating the return of production to developed economies, reversing the trend of offshoring.

-

On-Demand Production: The ability to produce goods as needed is reducing inventory costs and minimizing the risk of overproduction.

-

Circular Economy Integration: Micro-manufacturing’s emphasis on resource efficiency aligns well with circular economy principles, promoting sustainability in production.

Challenges and Limitations

While micro-manufacturing offers numerous advantages, it also faces several challenges:

-

Scalability Concerns: Some products may still require large-scale production to be economically viable.

-

Quality Control: Maintaining consistent quality across distributed micro-manufacturing networks can be challenging.

-

Regulatory Compliance: Navigating complex regulatory environments can be difficult for small-scale producers.

-

Skills Gap: The transition to micro-manufacturing requires a workforce with specialized skills in digital fabrication and advanced manufacturing technologies.

-

Initial Investment: While more accessible than traditional manufacturing setups, micro-manufacturing still requires significant upfront investment in equipment and training.

Micro-manufacturing Best Practices

• Invest in versatile, multi-purpose equipment to maximize flexibility

• Develop strong collaborative networks with other micro-manufacturers

• Prioritize continuous learning and skill development for your workforce

• Implement robust quality control systems across all production stages

• Leverage data analytics to optimize production processes and resource allocation

• Focus on niche markets where customization and rapid production are highly valued

• Explore hybrid models that combine micro-manufacturing with traditional production methods

As we look to the future, micro-manufacturing stands poised to play an increasingly significant role in the global industrial landscape. Its ability to offer customization, flexibility, and localized production aligns perfectly with emerging consumer trends and sustainability imperatives. While challenges remain, the potential of micro-manufacturing to revolutionize production paradigms is undeniable. Businesses that embrace this innovative approach may find themselves well-positioned to thrive in an era of rapid technological change and evolving market demands.